Moore’s molecular weight of component i in flow field NL: Furthermore, the in-depth heat and mass transfer involved during the various development stages of the fire are studied via simulation results.ĭiffusion coefficient of component i in flow field EVA:įourier transform infrared spectroscopy FR:

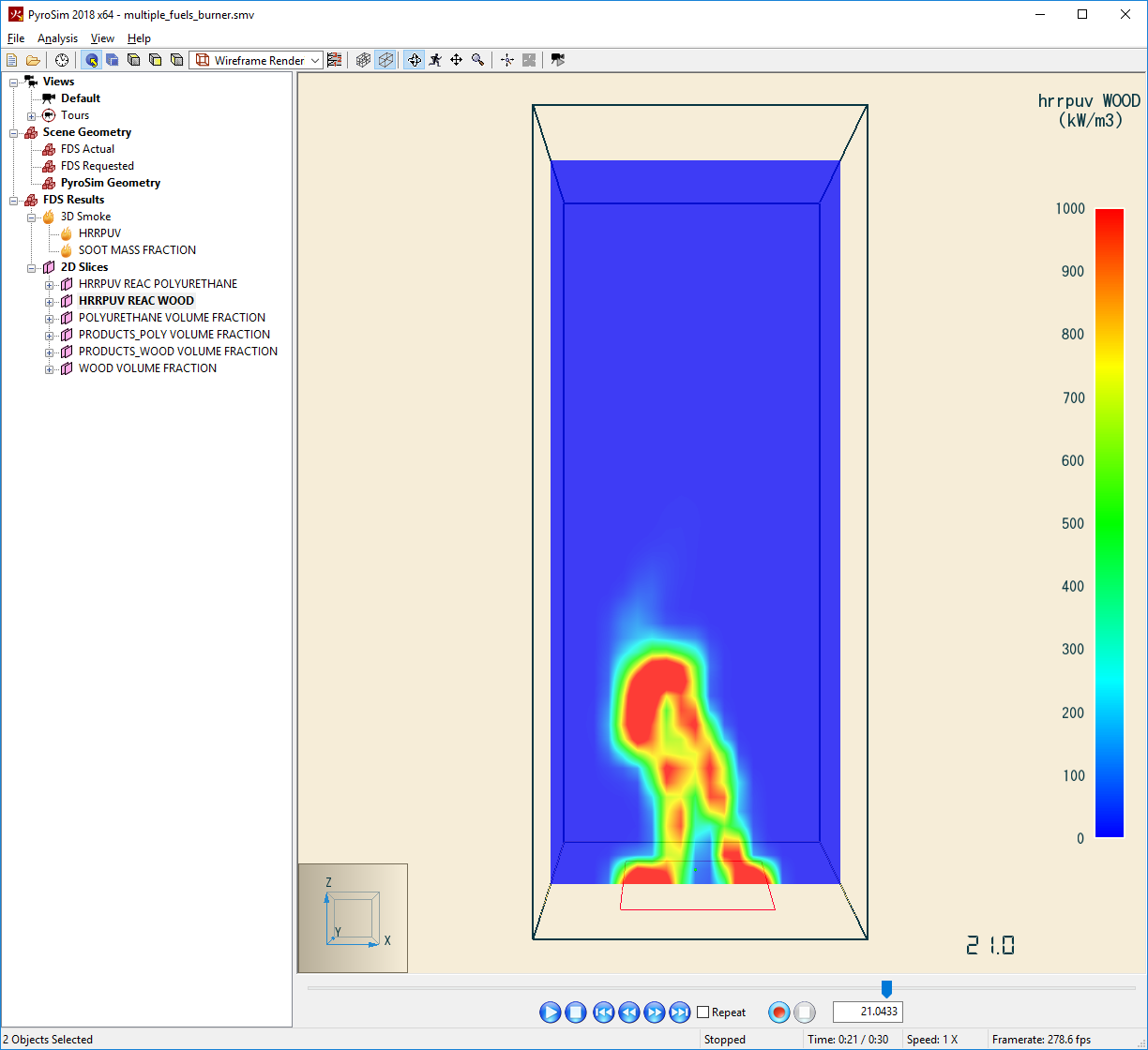

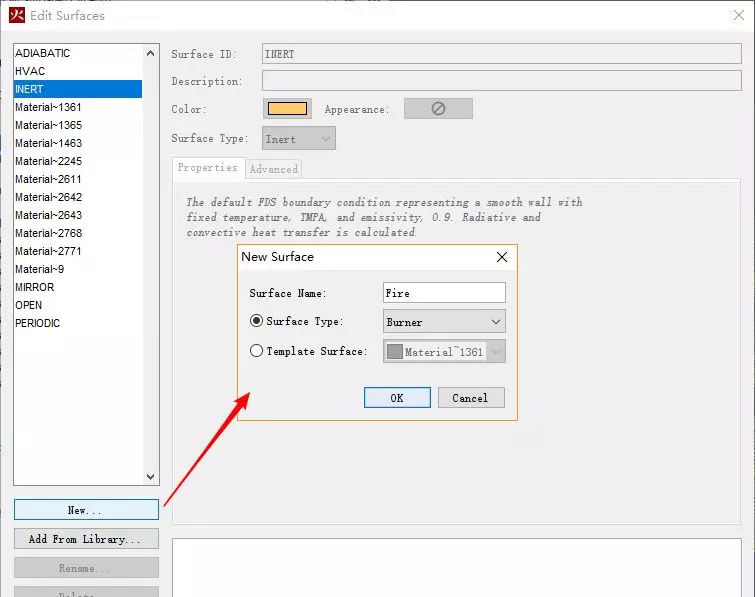

#REACTIONS IN PYROSIM SIMULATOR#

Furthermore, a fire dynamics simulator (FDS) model was constructed to study the burning characteristics of the selected materials numerically. In this study, cone calorimeter with Fourier Transform Infrared Spectroscopy (FT-IR) was performed on PU, PE and Ethylene–vinyl acetate (EVA) foam to (i) characterise the critical combustion performances and (ii) obtain real-time emission profiles of asphyxiant gases such as hydrogen cyanide (HCN), formaldehyde (HCHO), and acrolein, under flaming conditions. Thus, it is essential to gain an in-depth understanding of material flammability and gaseous product emissions, as well as the correlation against various radiant heat fluxes, temperatures and ventilation conditions. This is because the toxic emission of polymers, specifically carbon monoxide (CO), is responsible for most deaths and injuries in building fires. Nevertheless, the occurrence of fire in a confined environment surrounded by combustible polymeric materials can lead to disastrous consequences. Polymeric foams such as polyurethane (PU) and polyethylene (PE) are widely applied as upholstered furniture and wall insulations.

With the recent developments of composite polymer materials, the usage of synthetic materials in interior furnishing has rapidly increased.

0 kommentar(er)

0 kommentar(er)